Add to Cart

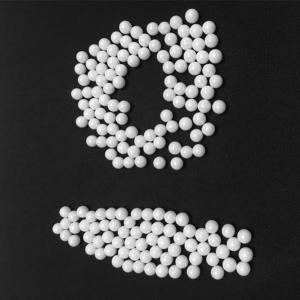

Grinding and dispersing ceramic zirconia grinding media balls and beads

| Item | Unit | Specification |

| Composition | wt% | 94.5% ZrO2 5.2% Y2O3 |

| Bulk Density | Kg/L | >3.6(Φ2mm) |

| Specific Density | g/cm3 | ≥6.02 |

| Hardness | Moh's | >9.0 |

| Elastic modulus | GPa | 200 |

| Thermal Conductivity | W/m.K | 3 |

| Crushing Load | KN | ≥20 (Φ2mm) |

| Fracture Toughness | MPam1-2 | 9 |

| Grain size | µm | ≤0.5 |

| Wear loss | ppm/h | <0.12 |

| Yttria stabilized zirconia beads Size (mm) | |||

| 0.08-0.12mm | 1.2-1.4mm | 2.4-2.6mm | 10mm |

| 0.28-0.35mm | 1.4-1.6mm | 2.6-2.8mm | 15mm |

| 0.4-0.6mm | 1.6-1.8mm | 2.8-3.0mm | 20mm |

| 0.6-0.8mm | 1.8-2.0mm | 3.0-3.2mm | 30mm |

| 0.8-1.0mm | 2.0-2.2mm | 4.8-5.3mm | 40mm |

| 1.0-1.2mm | 2.2-2.4mm | 7.8-8.3mm | 50mm |

| Zirconium Silicate beads Size (mm) | |||

| 0.4-0.6mm | 0.6-0.8mm | 0.8-1.0mm | 1.0-1.2mm |

| 1.4-1.4mm | 1.4-1.6mm | 1.6-1.8mm | 1.8-2.0mm |

| 2.4-2.6mm | 2.6-2.8mm | 2.8-3.0mm | 3.0-3.2mm |

A professional research and development production of zirconia products high-tech enterprises, covering 60,000 square meters, with intelligent multi-functional production plant 28,000 square meters; 700 square meters and 10,000 square meters R & D test center garden-style staff living quarters, is capable of independently produced powder, molding and sintering the fine processing of all production processes of large-scale manufacturers.

The company introduced isostatic pressing, flow Festival, gels, injections, grouting and other advanced molding equipment, using patented technology to produce high-performance structural ceramic products for its high hardness, high temperature, wear resistance, corrosion resistance, electrical insulation, non-magnetic, light weight and metal incomparable superiority, widely used in aerospace, nuclear industry, petroleum, chemical, textile, food, medical equipment, machinery and other fields.

grinding and dispersion of coatings and paints.

organic/inorganic pigments, e.g. titanium dioxide, ultra marine, iron oxide, etc.

pigments to dye textiles, plastics and food.

electric ceramics, e.g. barium titanate, piezoelectric ceramics, sensors, condensers.

medical technology, e.g. dentures and hip prosthesis.

magnetic ceramic, ferrite.

technical ceramic components, e.g. exhaust cultivator in engine technology.

dispersion of fungicides, herbicides, insecticides.

grinding of pigments and solids for lipsticks, skin and sun protection creams.

nano grinding for the production of active substances and supplies substances.

Recommendations for grinding applications

in high energy mills, like pin-mills.

for water-based milling products with low viscosity, low solids - like ink-jet.

in the food industry, for pharmaceutical products and cosmetics.

Features

Features

|

| Zirconia 95% | Zirconia 80% | Zirconia 65% |

|---|---|---|---|

| Metal Pollution | 0% metal pollution | 0% metal pollution | |

| Available Size(mm) | 0.1 - 0.4 mm 0.4 - 0.6 mm 0.6 - 4.0 mm 4.0 - 5.0 mm 5.0 - 6.0 mm 6.0 - 50 mm

|

0.6 - 4.0 mm 4.0 - 5.0 mm 5.0 - 6.0 mm |

0.6 - 4.0 mm 4.0 - 5.0 mm |

| Use | Ultra-fine grinding | Dispersing & grinding | Dispersing & grinding |

| Used for | High viscosity and hardness material |

Yttria stabilized zirconia (YSZ) grinding media – Overview

A unique material- for faster processing and less contamination

http://noboran.com/page.php?page=13/Yttria_Stabilized_Zirconia

Yttria (yttrium oxide,Y2O3) stabilized zirconia (zirconium dioxide, ZrO2) grinding media have high density, super hardness and excellent fracture toughness, enabling to achieve superior grinding efficiencies compared to other conventional lower density media.The purity,high chemical resistance and the extreme wear-resisting property of YSZ combined with proper surface conditioning of the grinding bodies effectively eliminates product contamination and lengthens media and mill life substantially. This unique combination of favourable features make good quality yttria stabilized zirconia grinding media especially suitable for sensitive products and critical applications.

Wide range of types and sizes- for a wide range of formulations

Our YSZ milling media are available in various shapes and size for any kinds of traditional and most high energy mills. (such as micro mill, ultra micro mill, jar mill, basket mill, ball, sand, pearl, disc and pin mill, planetary, vibratory and attrition ball mill, etc.) to grinding and disperse various materials effectively and economically.

YSZ grinding media are suitable for grinding and processing electric ceramics, piezoelectric ceramic, dielectric materials, battery raw materials and magnetic ceramics; toner materials, printing inks, UV inks, pigments, fillers, dyes, varnishes, paints and coating materials, high purity advanced ceramic materials, frits and glazes, pigments and solids for lipsticks, skin and sun protection creams, other cosmetic and toiletries, pharmaceutical, dental and foodstuffs; agrochemicals, pesticides, calcium carbonate, aluminum hydroxide, titanium dioxide, iron oxides, rare-earth and other materials. These media are particularly suitable for high viscosity wet grinding and dispersion. Yttria stabilized zirconia mico beads are suitable for nanoparticle production.

The most attractive media- for your most demanding needs

Our yttria stabilized zirconia grinding media are one of the highest qualities available, and represent the state-of –the –art in industry today.

For high viscosity and high percent solid formulations YSZ are the best grinding media: it increases productivity and lifespan of milling equipment. improves the quality of mill output, and can save lots of cost for long run even though the cost of initial charging is higher than for conventional lower quality media.

Yttria stabilized zirconia milling media are developed for today’s heavy-duty continuous mills demand, so that satisfy your most demanding needs.

Ceria stabilized zirconia

CSZ Grinding Media –overview

Ceria stabilized zirconia (CSZ) Grinding media- Overview

Ceria (cerium dioxide,CeO2)stabilized zirconia (zirconium dioxide ,ZrO2) is also a high-quality grinding medium.CSZ grinding media have highest density(6.2g/cm3) among the different types of ceramic grinding products.Due to this high density, it may be used to mill even high viscosity compounds, in which other media may float.

The high density allows smaller sized grinding bodies, resulting in more body per charge, and providing more contact points and narrower gaps between the bodies. This result in higher grinding efficiency and reduced grinding time.

Its physical properties like hardness, toughness, purity, chemical resistance and wear resistance are very similar to that of yttria stabilized zirconia grinding materials, I.e., CSZ has also superior grinding efficiencies and favourable properties compared to lower density media. Ceria stabilized grinding media can be used successfully for both horizontal and vertical mills.

Thanks to its excellent physical properties and lower price- compared to the YSZ- it can be favourably applied in several industrial fields. For example, for grinding CaCO3 for paper industry and other materials in the paint and ink industry.

SZS Mico beads

Zirconia silicate- zircon grinding media-overview

Zirconium silicate grinding media-overview

Zirconium silicate grinding media are popular, medium density (4.0g/cm3) products. Grinding beads are produced from specially formulated zirconium silicate, using a carefully controlled dripping technique followed by high temperature sintering and surface conditioning. Being a sintered bead, it does not have the problems that electro-fused beads have, such as broad size, bad roundness large pores, etc.

The combination of chemical composition, manufacturing process and surface conditioning yields good wear resistance, resulting in low contamination and improved cost effectiveness.

Compared with yttria stabilized or ceria stabilized zirconia beads, zirconium silicate has lower density and productivity but compared to aluminum beads, it has higher productivity, which makes it very economical.

It can be reasonably applied to every type of grinding machine (Vertical or horizontal)

Zirconium silicate grinding media is widely used in grinding of coatings, inks, dyestuffs, pesticides, cosmetics, titanium dioxide, magnetic materials, kaolin, calcium carbonate, fillings, and surface treatments.